Table 4 summarises the water quality issues in Australian meat chicken farms identified through targeted industry consultation.

Table 4. Summary of water quality issues in Australian meat chicken farms and common controls

| Issue | Comments | Common controls |

|---|---|---|

| High mineral or salts content causing scale | Commonly occurs in bore water from dissolving of naturally occurring chemicals in the aquifer. This, in turn, causes drinker blockages and leaking. | Reverse osmosis Additional flushing to manage blockages Descale between batches |

| Blackwater events | Commonly occurs in the lower Murray-Darling river. | Additional filtration and disinfectant |

| Microbial contamination | Commonly occurs in surface water from agricultural runoff and animal faeces contamination. Open storage systems (storage dams) are also a source of microbial contamination in the water treatment process. | Clean lines and treat water with additional disinfectant. |

| High organic matter | Commonly occurs in surface water. Surface water has a high disinfectant demand and higher microbial contamination risk. | Filtration |

| Algae blooms | Occurs in water bodies with high nutrient levels and temperatures. Common in dam water sources in summer. Filter was not cleaned regularly, and algae was getting into the water lines. | Filtration |

| Weather events causing water quality issues | Runoff increasing nutrient content in surface waters. | Additional filtration and disinfectant |

| Supply | Many regions across Australia are currently in drought. Water is generally scarcer, which increase costs. Additionally, in some areas, there is competition for water resource allocation. | |

| High iron or manganese concentrations | Caused by naturally occurring chemicals in the catchment or aquifer. High iron and manganese usually occur from bore water sources. Manganese can cause more severe scaling problems than iron. | Ion exchange Reverse osmosis Oxidation and filtration |

| Maintaining residual disinfectant | Inadequate pre-treatment and disinfectant dose | Monitoring and adjusting dose |

| Variable water quality | Surface water can have more variable water quality than bore water. | Several industry members prefer bore water because raw water quality is stable. |

| Uncertainty of disinfection | Some industry members did not monitor the success or efficiency of disinfection. | |

| Equipment failure | Drinkers have an average optimal lifespan of 5 years (i.e. they will work without major issues). Most growers replace drinkers after 10–15 years, which results in more broken or leaky drinkers. Air blocking pumps. | |

| Biofilms from medications and antibiotics | Medication and/or antibiotics can cause imbalances in microorganisms in the water lines. That is, antibiotics will kill all the bacteria in the water system, allowing for algae to increase, causing blooms. | Flush out system after medication or antibiotics |

| Biofilms from diet oil additives | Breeder oil diet additive caused biofilm. Lines were not cleaned or acidified after oil diet additive was given to breeders, which caused a biofilm in the water lines. | Fixed problem by acidifying water while birds were in the shed. Adopted a policy to flush after additives are administered. |

| Microbial failure | Disinfection incomplete, filters not working, drinker blocked when flushing. |

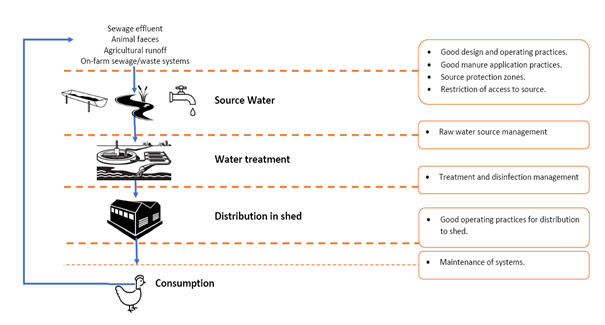

The ‘common controls’ identified in Table 4 are utilised at different stages of the farm water system. Figure 2 shows the key stages of the water management process at which controls and treatment can be employed, as well as potential sources of risk which may affect source water.