Website resources

Contact time calculator, United States Environmental Protection Agency

Contact time (Ct) calculations

Identification of suitable site-specific Ct values need to take the following into account:

- Raw water quality, i.e. organic matter, alkalinity, pH, etc.

- Expected variation in temperature, pH and organic matter-seasonal effects, weather events, etc.

- Pathogen profile in raw water

- Extent and performance of treatment before disinfection-organic matter removal

- Design and size of the contact tank

What is log inactivation?

Log inactivation is the number or per cent of microorganisms inactivated through the disinfection process and is a measure of the effectiveness of the disinfection process. It is influenced by variables including disinfectant concentrations, temperature, pH and disinfectant type. For example: a 4 log inactivation values means that 99.99% of microorganisms in raw water have been inactivated by disinfection.

Per cent reduction calculation

Per cent reduction = (A − B) [(A − B) × 100] ÷ A

Where:

A is the number of viable microorganisms before treatment

B is the number of viable microorganisms after treatment

Log reduction calculation

Log reduction (log10) = log10 (A ÷ B)

Where:

A is the number of viable microorganisms before treatment

B is the number of viable microorganisms after treatment

Convert log reduction to per cent reduction

P = (1 − 10-L) × 100

Where:

P is the per cent reduction

L is the log reduction

See Table 42 for tabulated values.

Table 42. Relationship of log reduction to percentage reduction

| Log reduction | Reduction |

|---|---|

| 1 | 90% |

| 2 | 99% |

| 3 | 99.9% |

| 4 | 99.99% |

| 5 | 99.999% |

| 6 | 99.9999% |

What is Ct?

Ct (minutes × mg/L) is a measure of the reaction time of the disinfection process. It is defined as the product of: C, the residual disinfectant concentration in mg/L (at the end drinker) and T, the disinfectant contact time in minutes. See Table 43 (below) for a description of the data required to calculate Ct.

Contact time

Ct = concentration × time

Where:

Concentration is disinfection residual

Time water is in contact with the disinfectant

Table 43. Data required to calculate Ct

| Parameter | Unit |

|---|---|

| Peak hourly flow, Q | litres per minute (Lpm) |

| Residual disinfectant concentration, C | mg/L |

| Disinfectant type | N/A |

| Temperature | °C |

| pH | standard units (s.u.) |

Ct and log inactivation calculation overview

Step 1—Calculate detention time

Step 1A—Calculate theoretical detention time (TDT)

TDT = V ÷ Q

Where:

TDT = theoretical detention time (minutes)

V = volume, based on low water level

Q = peak hourly flow

Step 1B—Calculate actual detention time (T)

T = TDT × BF

Where:

T = actual detention time (minutes)

TDT = theoretical detention time (minutes)

BF = baffling factor (a measure of short-circuiting). See Table 44 for typical baffling values.

BF = T10 ÷ TDT

Where:

TDT = theoretical detention time (minutes)

T10 = the time taken for 10% of the incoming water to exit the tank

Table 44. Typical baffling conditions (The Standards and Guidelines for Municipal Water, Wastewater and Storm Drainage Systems, AENV 1997)

| Baffling condition | T10/T ratio | Baffling description |

|---|---|---|

| Unbaffled (mixed flow) | 0.1 | None, agitated basin, very low length to width ratio, high inlet and outlet flow velocities |

| Poor | 0.3 | Single or multiple unbaffled inlets and outlets, no intra-basin baffles |

| Average | 0.5 | Baffled inlet or outlet with some intra-basin baffles |

| Superior | 0.7 | Perforated inlet baffle, serpentine or perforated intra-basin baffles, outlet weir or perforated launders |

| Perfect (plug flow) | 1.0 | Very high length to width ratio (pipeline flow), perforated inlet, outlet, and intra-basin baffles |

Step 2—Calculate CtCALC

CtCALC = C × T

Where:

CtCALC = concentration time, calculated value (minutes × mg/L)

C = residual disinfectant concentration measured during peak flow (mg/L)

T = actual detention time (minutes)

Step 3—Calculate Ct99.9

Step 3A—Determine Ct required for specific microbe 3 log reduction (Ct99.9) using look-up tables and water treatment plant information.

The Ct required for 3 log inactivation of a specific microbe (designated as Ct99.9) is available in tables for different disinfectants, as shown in Watson et al. (2019). The Ct99.9 depends on the species of microorganisms targeted, type of disinfectant, residual disinfectant concentration (C), temperature, and pH.

For example, using Table 45 to look up the Ct for a 3-log reduction (Ct99.9) for Giardia lamblia for water with a 0.8mg/L chlorine residual and a pH of 7.5 at 0.5°C would be 246.

CtCALC > Ct99.9 indicates that the water system is meeting at least 3 log microbe inactivation.

Table 45. Example of Ct table for Giardia lamblia 3 log reduction (Ct99.9) for free chlorine at 0.5°C

| Temperature = 0.5°C | |||||||

|---|---|---|---|---|---|---|---|

| Disinfectant concentration (mg/L) | pH | ||||||

| ≤6.0 | 6.5 | 7 | 7.5 | 8 | 8.5 | 9 | |

| ≤0.4 | 137 | 163 | 195 | 237 | 277 | 329 | 390 |

| 0.6 | 141 | 168 | 200 | 239 | 286 | 342 | 407 |

| 0.8 | 145 | 172 | 205 | 246 | 295 | 354 | 422 |

| 1.0 | 148 | 176 | 210 | 253 | 304 | 365 | 437 |

Step 3B—Calculate log inactivation ratio

Log inactivation ratio = CtCALC ÷ Ct99.9

Where:

CtCALC = concentration time, calculated value (minutes · mg/L)

Ct99.9 = concentration time to inactivate 3-log of specific microbe (minutes · mg/L) from table

Example log inactivation calculation

Measured at peak flow:

Peak flow, Q = 250L/min

Free chlorine residual, C = 0.8mg/L

pH = 6s.u.

Temperature = 0.5°C

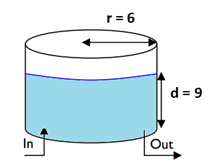

Cylindrical basin information:

Inner tank radius, r = 6m

Minimum tank water level, d = 9m

No baffling, BF = 0.1

Background – calculate basin volume, V

V = π × d × r2, cylindrical basin volume equation

V = 3.1416 × 9m × (6m)2 = 1017.9m3

V = 1017.9m3 × 1000L/m3

V = 1,017,870L

Step 1—Calculate detention time

Step 1A—Calculate TDT

TDT = V ÷ Q

TDT = 1,017,870 L ÷ 250L/min

TDT = 4,071.48 minutes

Step 1B—Calculate actual detention time

T = TDT × BF

T = 4,071.48 minutes × 0.1

T = 407.148 minutes

Step 2—Calculate CtCALC

CtCALC = C × T

CtCALC = 0.8mg/L × 407.148 minutes

CtCALC = 325.72 minutes·mg/L

Step 3—Calculate specific microorganism log inactivation (e.g. Giardia lamblia)

Step 3A—Determine the Ct required for Giardia lamblia 3 log reduction

Determine Giardia lamblia Ct99.9 from Ct Table 45 at temperature = 0.5°C, pH = 6s.u., free chlorine residual = 0.8mg/L.

Ct99.9 = 145 minutes·mg/L

Step 3B—Calculate Giardia lamblia log inactivation ratio

Giardia lamblia log inactivation ratio = CtCALC ÷ Ct99.9

Giardia lamblia log inactivation ratio = 325.72 minutes·mg/L ÷145 minutes·mg/L

Giardia lamblia log inactivation ratio = 2.24 ratio

The Giardia lamblia log inactivation ratio is >1. Therefore the water system is meeting at least 3 log virus inactivation for Giardia lamblia.