The location of a composting site has a major influence on its environmental and economic performance. Inadequate site selection for poultry composting can also cause a higher risk of biosecurity breaches.

It is most important to match the feedstock to be composted with the appropriate technology and the needs of the site. Because most poultry wastes are potentially highly odorous, strict biosecurity protocols must apply.

Other considerations are:

– The capacity of the proposed technology to manage odour and dust emissions

– The scale of the proposed operation

– The distance of the proposed site to residential areas, other poultry facilities or other sensitive land uses (‘buffer distances’)

– The prevailing wind direction, wind speed and cold air flows

– The distance of the proposed site to surface waters (should be >100m) and

– The vulnerability of groundwater to leaching and pollution.

An important feature of any facility is the separation of functional areas for the performance of similar tasks. Functional areas reflect the main activities of composting.

These can be broken broadly into the following areas:

– Preparing compost mix

– Composting

– Curing and

– Machinery washdown space.

Each functional area has different organisational and technical characteristics depending on the proposed feedstock, scale of operation, and composting technology.

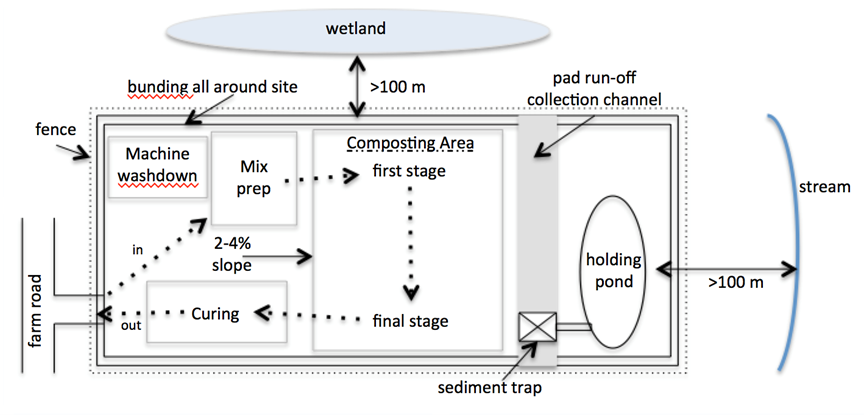

An example of a suitable layout for an on-farm open windrow/pile composting operation is shown in Figure 4. The entire site should be bunded to divert stormwater outside the composting area. The surface should be made from graded and compacted soil or gravel (minimum 15–20cm thick).

The example layout has a holding pond to collect leachate and rain from the bunded area. Water in the holding pond can be used to irrigate the compost piles when necessary. An alternative to a holding pond is a professionally designed vegetation strip, like those used for the treatment of effluent from septic systems.

In this example, the curing area is small compared to the main composting area because it assumes that compost will be stacked here in deep piles for a brief period only (e.g. 4 weeks or so). After this, the compost can be stored outside the facility boundary without issue.

In addition, the following characteristics should be considered:

– The site should be at least 100m from waterways, at least 200m from other farm buildings and more than 2000m from neighbouring poultry farms.

– The installation of fencing is recommended to keep out scavengers.

– The mix preparation area should be separately contained (e.g. by more bunding or walls) to prevent cross-contamination between feedstock and finished compost. If mortalities are composted, sufficient absorbent organic material, such as sawdust or spent poultry litter, should be stored here to quickly cover incoming carcasses.

– The composting process in the composting area should follow a set directional flow, with ‘fresh’ compost at one end and finished compost at the other.

– Some compost facilities for mortalities are designed with roofing. While this is ideal, it is not necessary in all cases, but it may be prudent in high-rainfall climates.

– A machine washdown space ensures that cross-contamination does not occur when using machinery in different operational areas around the site and the rest of the farm.

These are general guidelines. Check with your state EPA, agriculture department or local government for regulations and/or guidance specific to your plans.