Industry growth and location

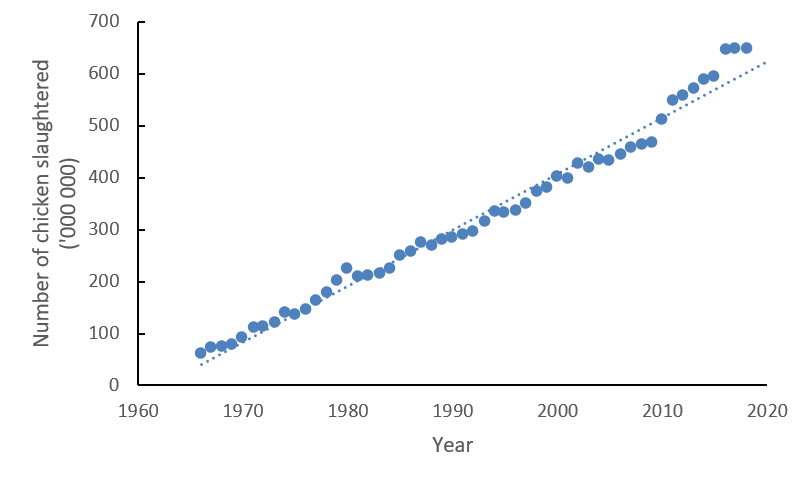

Australia’s production of chicken meat has increased by more than 160% over the past 20 years. Chicken meat is now Australia’s most significant source of meat protein, with 90% of the population consuming chicken meat at least once a week (ACMF, 2014). As there is minimal import or exports of chicken meat in Australia, effectively all chicken consumed in Australia is locally produced. The Australian Chicken Meat Federation (ACMF) forecasts a continual, steady growth in domestic production and consumption of Australian chicken meat (ACMF, 2011), which is supported by ABS statistics as shown in Figure 13.

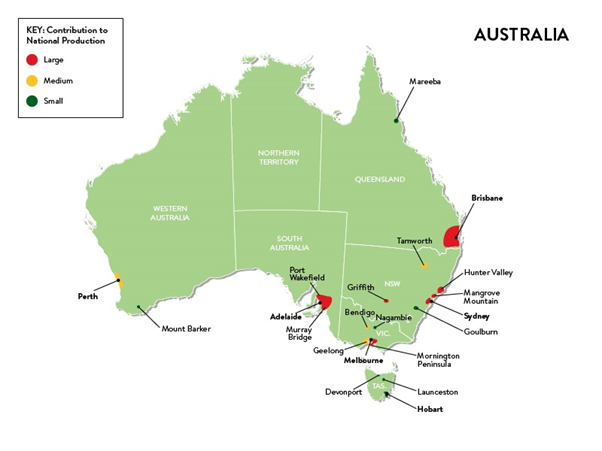

The Australian chicken meat industry is largely integrated, and companies own or control most aspects of their supply and production chain. Large chicken meat companies may have breeder farms, hatcheries, chicken meat farms, processing plants, feed mills and laboratories. Smaller companies will have some of these facilities and use third parties for others. The larger Australian chicken companies sub-contract the growing stage of production. Chicken meat growing farms are generally located within 200km of a processing plant, near a feed mill, with guaranteed water, power and access to services. The region where chicken meat is produced dictates the availability, type and cost of litter that is used. The major chicken meat producing regions of Australia are outlined in Figure 14.

Production cycle

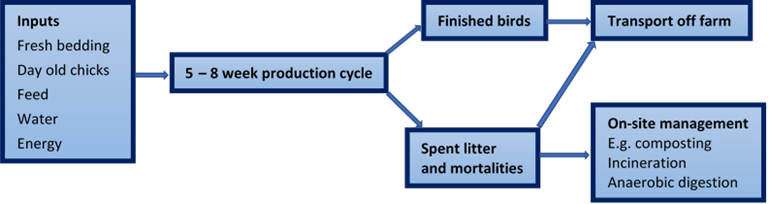

Meat chickens are typically delivered to the farm as day-old chicks, and are grown in enclosed sheds for 5–8 weeks, when they are harvested and transported off-farm for slaughter. Meat chickens may be harvested at several points throughout the growth cycle, called a ‘pick-up’, once they meet the desired weight. A period of 1–2 weeks is typical between growth cycles, with sheds cleaned and disinfected between production cycles.

The typical inputs and outputs for a production cycle are shown in Figure 15.

Role of litter

Meat chickens move freely within sheds and are not housed in cages but on bedding material or litter typically composed of organic material such as wood shavings, sawdust or straw. The industry uses a variety of litter types, which may vary between regions due to accessibility. The most common types of litter used in Australia are wood shavings, recycled wood chips, sawdust, cereal straw and rice hulls. The ability to source sufficient volumes of litter at a suitable price is a constant area of interest for the industry. See Review of fresh litter supply, management and spent litter utilisation (Watson & Wiedemann, 2018) for more information on litter types.

Spent litter from meat chicken farms is typically removed from sheds at the end of each growth cycle, but can be re-used for several growth cycles in some systems – refer to Litter reuse: an evidence-based guide to reusing litter (Wiedemann, 2015c) for more information. Because spent litter contains manure from the production cycle, it can be used in a variety of agricultural applications. Spent litter management options available to farm operators include off-site disposal, stockpiling, composting, incineration, anaerobic digestion and spreading on-farm.